Chlorinated Polyvinyl Chloride (CPVC) Pipes

Corzan HP-Champro

Description

CPVC Industrial systems are produced from specialty plastic compounds known as post-chloronated polyvinyl chloride (CPVC) manufactured by The Lubrizol Advanced Materials. The compunds shall meet cell class 24448 as defined by ASTM D1784 and have a design stress of 2000 pso and a maximum service temperature of 200 ° F.

The compound shall be listed by the National Sanitation Foundation for use with portable water in accordance with NSF Standard 14. The colour is light gray.

Pipe

Pipe shall meet or exceed the requirements of ASTM F441 in Schedule 40 and 80 dimensions. Available in size range 15mm (1/2") to 300mm (12").

Fittings

Fittings shall meet or exceed requirements of ASTM F437 (Schedule 80 threaded) or ASTM F439 (Schedule 80 socket). Available in size range 1/2" to 12"

Primer / Solvent Cement

All socket type joints shall be made up employing primer and solvent cements that meet or exceed the requirements of ASTM F656 and ASTM F493. Both primer and solvent cement shall confirm with the requirements of NSF standard 14. Only CPVC primer and solvent cement shall be used when making CPVC solvent cement joints.

Marking and uniformity: Pipe and fittings made from ASTRAL ® HP CPVC compounds shall be clearly marked with the manufacturer's name ot trademark, material designation applicable ASTM Standard.

BASIC USE

ASTRAL CORZAN. HP CPVC pipe and fittings are intended for use in both pressure and drain applications in general chemical manufacturing plants, pulp and paper plants, waste water treatment plants, power plant, fertilizer, metal treating/electroplating plants, water purification plants, and food processing plants where excellent resistance to corrosion from a wide range of chemicals, acids, and bases at temperatures upto 200 °F is required.

SYSTEM DESIGN

System design shall be in accordance with standard industry practice for thermoplastic industrial piping systems and shall take into consideration such factors as pressure and flow requirements, friction loss, operating temperatures, support spacing, anchoring, bracing and thrust blocking, temperature correction factors, joining methods, chemical environment, collapse and loading, and thermal expansion and contraction.

Limitations

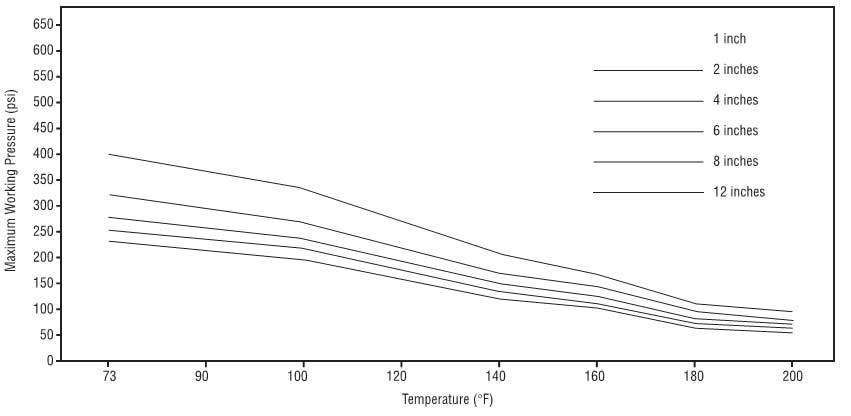

- Air or compressed gas shall never be used for pressure testing rigid thermoplastic piping systems. Temperature correction factors shall be applied when operating .mperatures exceed 73 °F.

- Only Schedule 80 pipe may be threaded up to and including 4"size, and threads shall be in accordance with ANSI B1.20.1 Taper pipe Thread. Only water soluble oil or water shall be used when threading Corzan pipe.

- Digressing type solvents shall never be used to clean threads. $ Only Teflon tape shall be used when making plastic threaded connections. Flanged systems shall not exceed 150 psi working pressure.

- Threaded joints shall have 50% of the pressure rating of Schedule 80 pipe. ASTRAL CORZAN. HP CPVC is not recommended for use with most polar organic solvents such as chlorinated or aromatic hydrocarbons, esters, or ketones. Prior testing is recommended when required service includes surfactant, oil, or grease. Consult Astral for specific chemical resistance information.

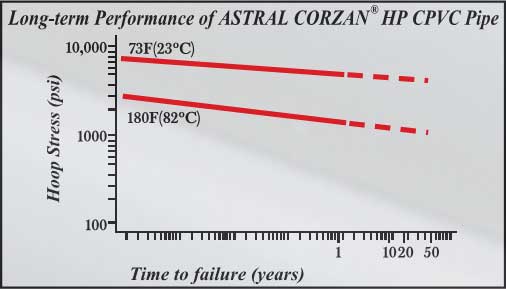

Fig: 1.2

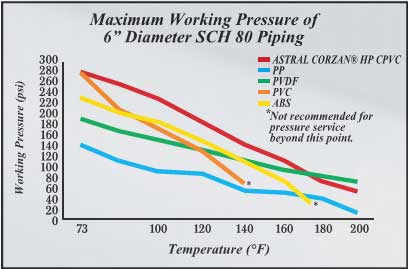

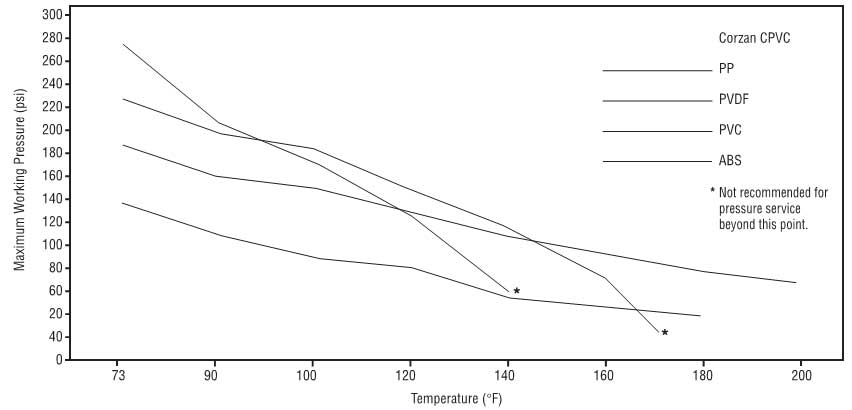

Fig: 1.4

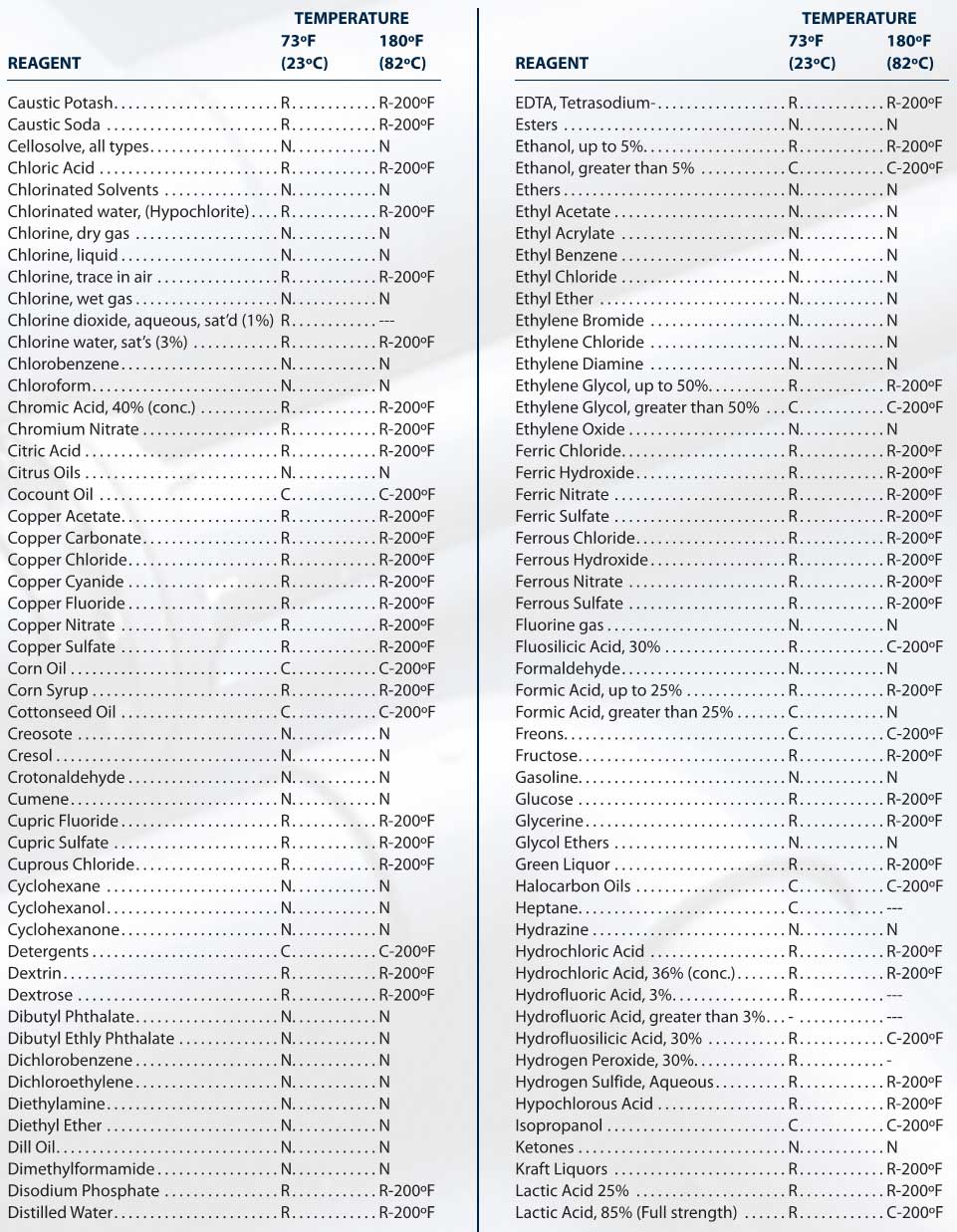

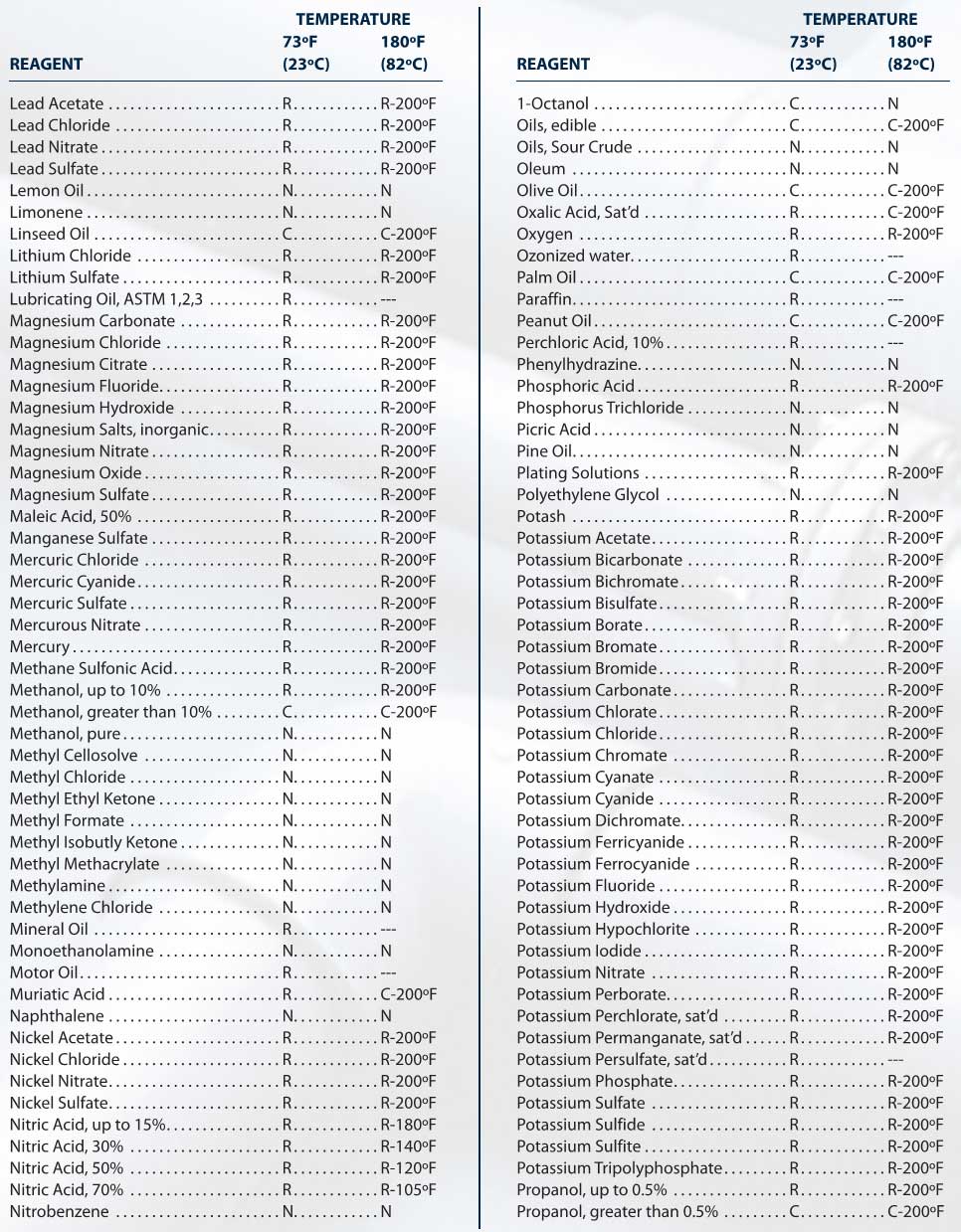

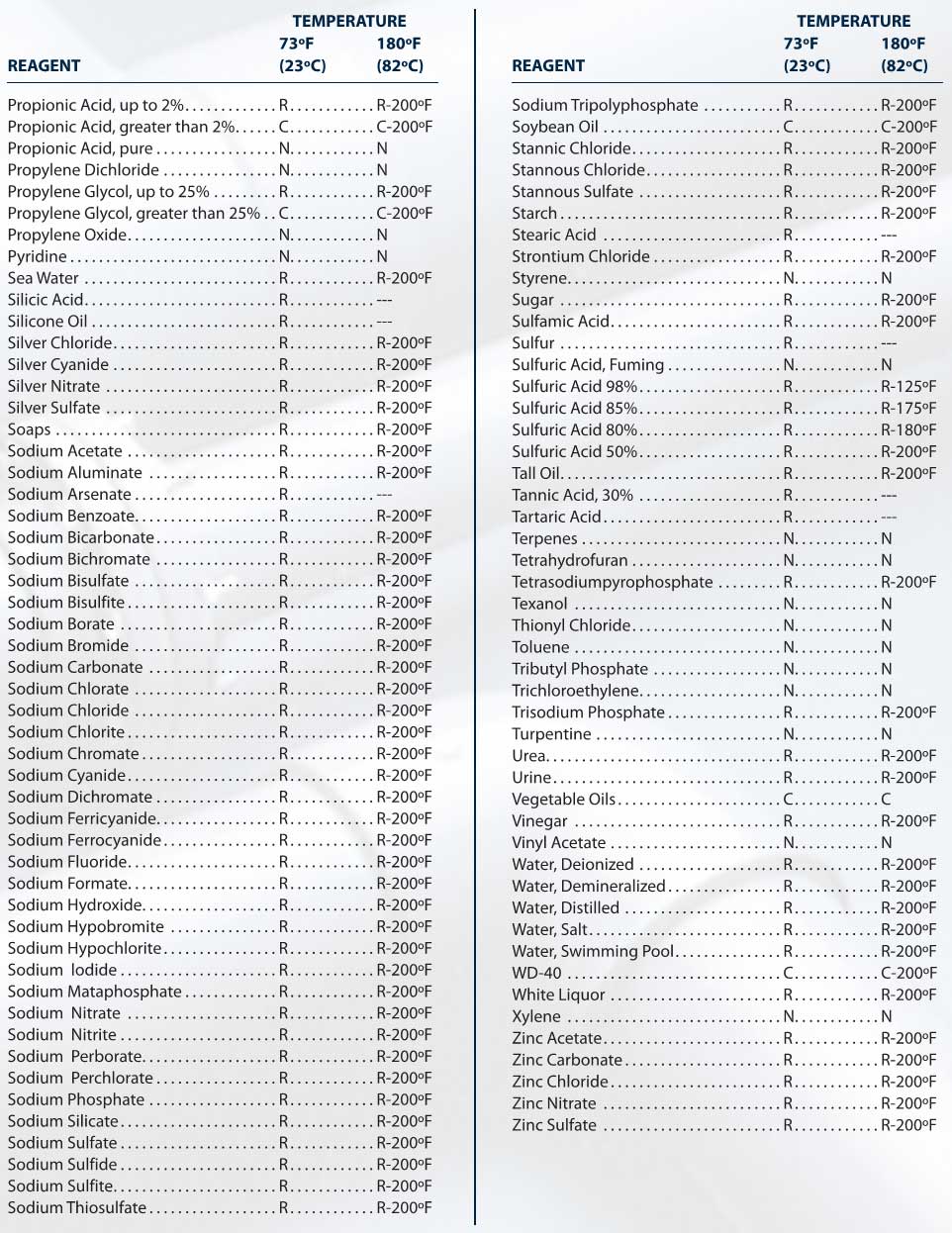

Chemical Resistance of Astral Corzan® HP CPVC

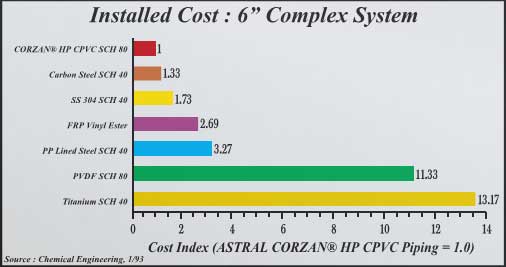

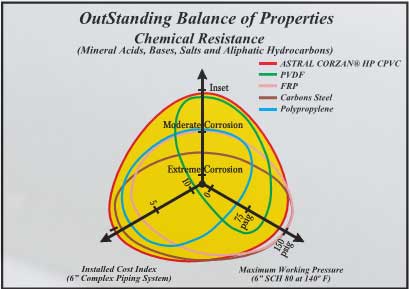

One of the key advantage of ASTRAL CORZAN° HP CPVC is its execellent resistance to a broad range of corrosive environments. By replacing traditional materials with ASTRAL CORZAN® HP CPVC, engineers can extend equipment service life and reduce maintennace, while minimizing process life-cycle costs. This technical report is intended to provide engineers and end-users with guidance as to the suitability of ASTRAL CORZAN® HP CPVC industrial piping systems in corrosive applications.

Specific use conditions must also be considered since these will determine the chemical resistance of any thermoplastic piping system.Variables that can affect chemical resistance include chemical concentration, temperature, pressure, external stress, and final product quality. Since the number of possible use conditions is so large, the final decision regarding material suitability often must be based on in- service testing.

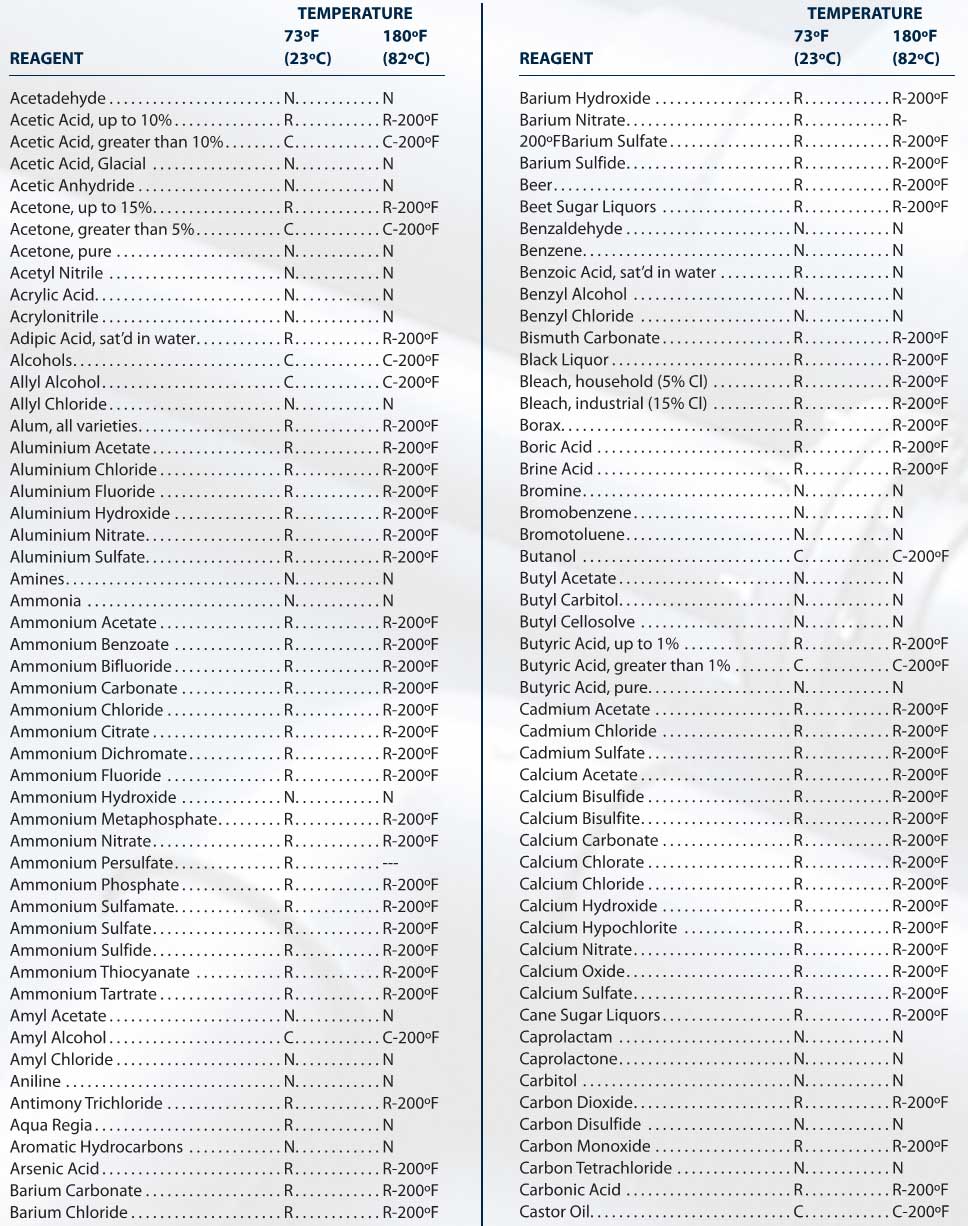

The information contained in this report was developed to include conditions that are most often encountered in industry. CPVC samples were immersed in the particular reagent for at least 90 days at 73°F(23°C) and 180°F(82°C). Changes in weight and tensile strength for each sample were reviewed in conjunction with field experience and information gathered from various sources to develop recommendations shown. Note that these recommendations are based on specific use conditions and may not apply to all situations. For this reason,the final decision regarding material suitability must rest with the end- user.

The notes following the chemical resistance chart list specific areas where caution must be used when considering ASTRAL CORZAN® HP CPVC. Additional chemical resistance data will become available as testing of ASTRAL CORZAN® HP CPVC continues. Consult with your product supplier or for the latest ASTRAL CORZAN® HP CPVC chemical resistance information.'

Table 2.1

CPVC is not recommended for use with most polar organic materials including various solvents i.e., chlorinated or aromatic hydrocarbons, esters, or ketones. Resistance of CPVC to certain other fluid mixtures such as fuel oils with moderate aromatic content cannot be determined on basis of immersion testing alone. Actual use data must be obtained. There are a number of similarities in chemical resistance between PVC and CPVC materials. However, one must exercise caution when comparing the chemical resistance properties of CPVC to those of PVC, which are not always the same.

Table 2.2

CPVC test samples exposed while under stress to surfactants, certain oils, or grease have shown signs of environmental stress cracking. Environmental stress cracking is a situation in which the manufactured pipe or fittings are weakened by contact with certain chemicals and propagated by external stresses. External stresses include not only the known pressure stress on a system but also stresses from sources such as expansion and installation.When CPVC is intended for use in handling such chemicals, special consideration should be taken during design and installation to avoid unusual stresses in the piping system,or advance testing of the chemical in simulated use conditions is strongly suggested. Certain organic solvents which are soluble with water, such as alcohols, may safely be handled below a certain concentration. Many of these limiting concentrations are noted in the chemical resistance table. Solvents which are insoluble in water, such as aromatics, will be absorbed by the piping over time, even when they are present at very low levels in the water. This will lead to a decreased service life expectancy for the system.

Table 2.3

The full hydrostatic pressure rating of the pipe may not apply to the entire range of temperature and concentration designated as "recommended."

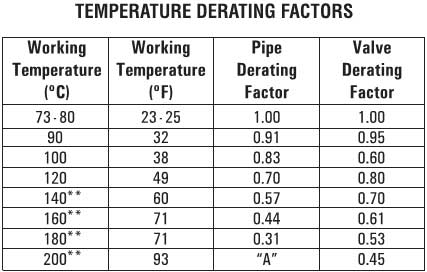

Table 2.4

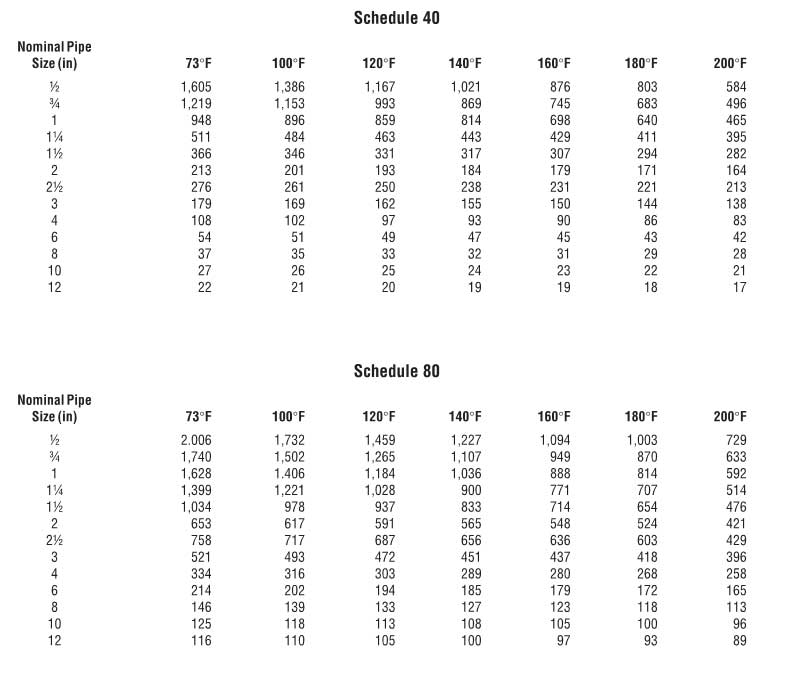

Pressure Ratings for CPVC Valves:

Corzan valves will typically be rated to either 150 psi or 225 psi at 73 °F. Derating factors for higher temperatures are shown here. Contact your valve manufacturer for specific information on ASTRAL CORZAN ® HP CPVC valves.

Pressure Ratings for Flanged Systems:

Flanged systems of any size should not exceed 150 psi working pressure.

Pressure Ratings for Threaded Systems:

Threaded systems are derated to 50% of the pressure rating for the piping at the system operating temperature.

Note: "A" Consult with specific product or component manufacturers for temperature derating factors above 180 ° F (82 ° C)

Note: "A" Consult with specific product or component manufacturers for temperature derating factors above 180 ° F (82 ° C)

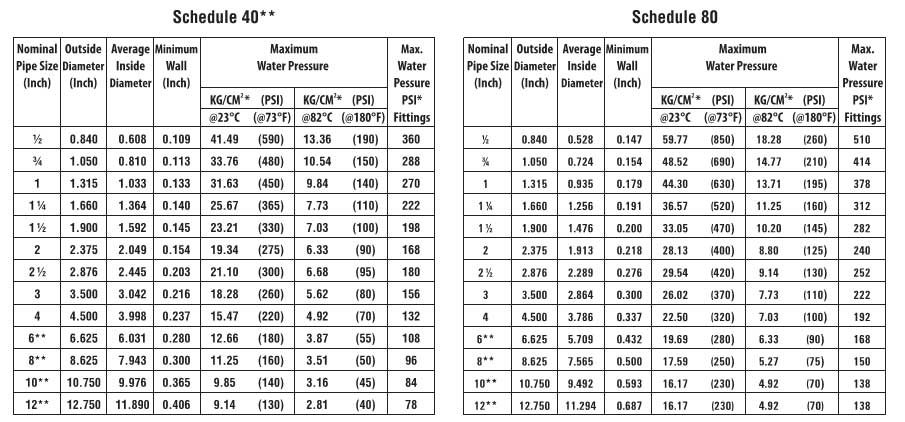

Pipe Dimensions & Pressure Ratings

Table 3.2

Thermal Expansion & Thermal Stress

Thermal Expansion

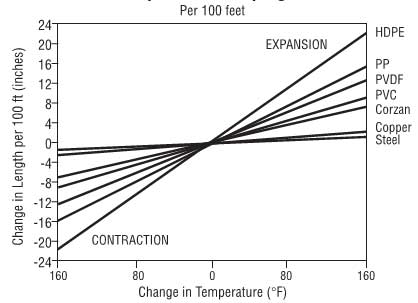

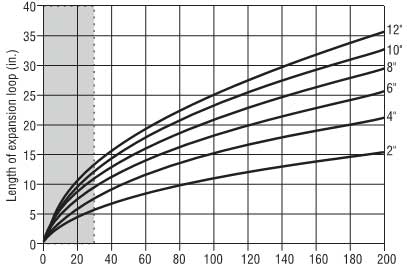

It is important to considerthermal expansion when designing a system with ASTRAL CORZAN® HP CPVC pipe. Most therm° stics have a coefficient of thermal expansion which is significar higher than those of metals. However, ASTRAL CORZAN® HP CP has the lowest thermal expansion of any commonly used thermoplastic.The thermal expansion of a piping system subjecl a temperature changecan therefore be significant, and may ne compen- sation in the system design

Thermal Stress

Thermal Stresses If thermal expansion is not accommodated, it is absorbed in the pipe as an internal compression. This creates a com-pressive stress in the pipe. The stress induced in a pipe which is restrained from expanding.

Chart 4.1